CNC machining revolutionizes the manufacturing and design of intricate parts. Australia is leading the way in this technological advancement. It is a result of CNC Machines and CNC Mills.

CNC machineries are based on the principle that subtractive manufacturing is more efficient than adding material. The process sculpts raw materials into beautiful components by removing them rather than adding. CNC Machines are the marvel of technology at the center of this technological advancement, are the foundations of manufacturing precision.

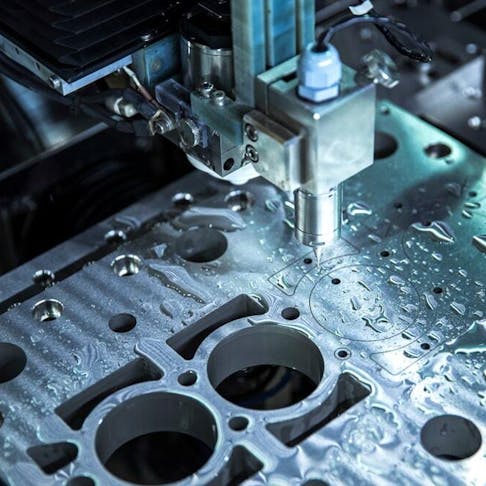

CNC machines are controlled by digital computers that control, automate, and control industrial machines. The digital code is used to direct the high-speed cutters of the machine which transforms a solid piece of material into its shape you want it to be. Computers and CNC Machines work together in large-scale industrial plants and seamless integration improves efficiency and productivity.

The mechanics are fascinating and complex. CNC Mills use high-speed cutters to meticulously carve the desired shape out of the solid material. CNC machining is preferred by industries that require accuracy because of the precision it achieves.

The CNC Machine sector in Australia is booming thanks to cutting-edge technology, a vibrant industry and a thriving culture. CNC Machine Australia is an innovation hub where industries such as aerospace electronics, automotive and electronics rely on CNC machine tools to attain unbeatable precision and efficiency.

CNC Mills can play a crucial part in shaping the manufacturing sector of tomorrow. CNC Mills that are controlled by computerized codes and create precise components for various industries, show flexibility. CNC Mills have become indispensable tools for engineers and manufacturers because of their effectiveness and precision.

CNC Machining is a multi-faceted procedure that has advantages above the traditional manufacturing. One of the main benefits is the capability to create extremely intricate and complex components with a consistent level of accuracy. CNC Machines can also be used for rapid prototypes, as their digital nature allows them to be more efficient and cost-effective than traditional manufacturing methods.

CNC Machine Tools contributes significantly to the efficiency in CNC machine machining. They are a variety of instruments used in the machining process, from drilling and finishing to cutting and shaping. Synergy between CNC Machines, CNC Machine Tools and CNC Machines ensures a smooth process that increases precision while minimizing waste.

Industries from all sectors have adopted CNC machining for its revolutionary capabilities. In the aerospace industry, CNC machining plays a crucial role in the creation of complex components that require the highest level of precision and dependability. CNC machining’s efficiency is beneficial for the energy sector which produces complex components for machinery and other infrastructure.

CNC Machining’s versatility is evident in the automotive and electronic industries. CNC machines are able to meet the requirements of both the automotive and electronic industries. CNC machining has a variety of uses, including making electronic circuits as well as engine components.

In conclusion, CNC machining has redefined the landscape of modern manufacturing, with CNC Machines, CNC Mills as well as CNC Machine Tools standing as the pillars of the technological revolution. CNC machines’ precision, efficacy and adaptability continue to shape the future of engineering Australia and across the globe. They are paving the way to excellence and innovation across industries.